Seafood cold storage warehouse is more and more popular in Philippines nowadays ,the surrounding environment around the sea created the advantage of its fishery. Philippines is our traditional market, up to now we have built more than 10 sets large projects and our customers cover fishery,coffee ,poultry business and etc. The first set has been installed in 2010, and it is running smoothly at present. For one complete production line for seafood cold storage warehouse should include working area, loading bay , freezer room, blast freezer,prepare room,ante room and etc. For one smooth flow, receiving the fresh seafood in loading bay,then put into prepare room or working room to put down the temperature ,then put in blast freezer for quick freeze ,finally ,put it into freezer room for a long time storage .

Characteristics of Seafood cold storage warehouse :

Working area :

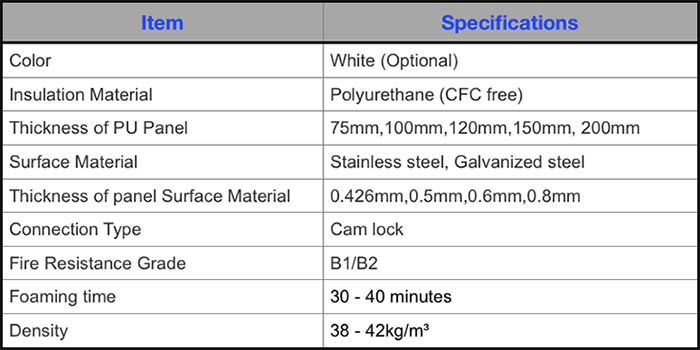

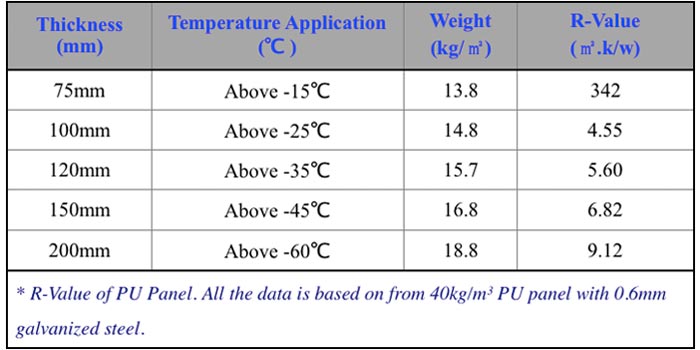

For seafood treatment,it will release of acid and other corrosive substances, should have high request for inside PU panels and evaporator . In this situation, we use stainless steel for inside pu panels and the cover for evaporator ; for fins of evaporator, use hydrophilic aluminum foil (blue color) which has anti-corrosion effect .

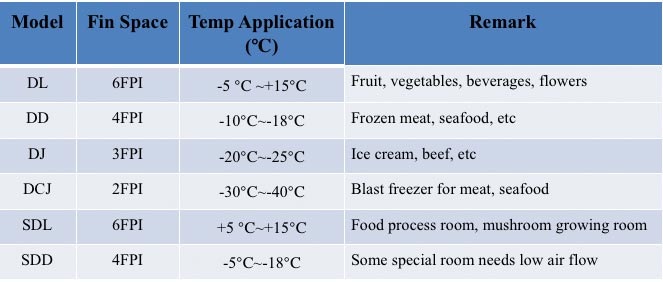

Another point is there has people working inside, in order to protect people from strong wind blowing directly , the evaporator air flow must be softly blow out ,so we will use dual throw model (SDL series)evaporator for working area . SDL series are used in food process workshop ,the temperature is above +2℃.

Blast freezer

Blast freezer for seafood cold storage warehouse:

In order to keep the good taste and keep in a long time storage , fresh seafood before put into the freezer storage should be quick freezed in blast freezer first,after 5-8 hours ,the core temperature can become -18 ℃,then put it into keeping freezer for a long time storage ;

Normally , blast freezer dimensions will be small size , we will use land type evaporator . This design will save some space and make the air flow more balance .

Keeping freezer for seafood cold storage warehouse :

After quick freeze in blast freezer ,it will be stored in keep freezer (-20℃)for a long time .

New design with our engineer, Europe style color with strong tunnel fans,large air flow.

Anti-corrosion fins with blue color .

41mm wall thickness for coppoer pipes .

Rack unit

Rack unit :

Known that poor water quality in Philippines,evaporative condenser is not very suitable for this environment using , so we use the air cooled model ;multiple units can use a siphon device to simplify the system design.

Thermosiphon refrigeration cycle (also known as heat circulation refrigeration cycle) used in screw compression refrigeration system. is most suitable for the system with poor water quality. Its characteristics are: small size and reliable oil cooling. The oil temperature after cooling is generally in 10 ℃to 20 ℃ higher than the condensing temperature. Compared with water cooling, no cooling water is needed and water system is simplified; there is no problem of heat exchanger tube scaling to affect the heat transfer of oil cooler, and the cooling efficiency can be improved; there is no influence on the exhaust volume and power consumption of the compressor.

To sum up, thermosiphon refrigeration cycle is a developed energy-saving refrigeration system for cooling refrigerating oil recently. At present, many foreign countries have adopted it.

PLC system ,easy to debugger and maintain .

For loading bay :

Mainly need to receive and delivery the seafood, use roll up door that connect with shipping truck or container .

For one complete roll up door, includes door body , lifting platform and edge package.

Usually keep it in +8℃room temperature .

Door size and lifting platform should depend on the truck or container size to design.

For basic cement platform building , it should depend on the height of shipping truck .

For back up parts :

For large seafood cold storage warehouse project, there are consumables need to back up, it includes compressor, fan motor for evaporator , fan motor for condenser, heater,PLC system and etc ;

The meaning of OnlyKem in Chinese is grateful,promise and success, OnlyKem don’t want to only be a successful businessman, we would like to be skilled craftsman .As we think as long as taking customer needs as a primary task,have a heart of gratitude and sincerity, the result won’t be bad . The idea of making a perfect machine is always fascinating for us .Our stable quality ,competitive price and immediate service help us possess more and more customers . In the future, we believe that you can see more and more OnlyKem seafood cold storage warehouse will be building in Philippines and also other countries !